Innage Oil Gauging Tapes and Outage Oil Gauge Tapes

There are 2 oil tapes to manually measurre the level of liquids in a large container using an oil gauging tape – Innage or Outage.

There are three basic operations that are conducted by tank gauging tape:

- How much liquid is already in the container? (Innage)

- How much more liquid can be put in the container? (Outage)

- When the liquid is oil, how much water has displaced oil in the bottom of the container?

The Innage Oil Gauging Tapes

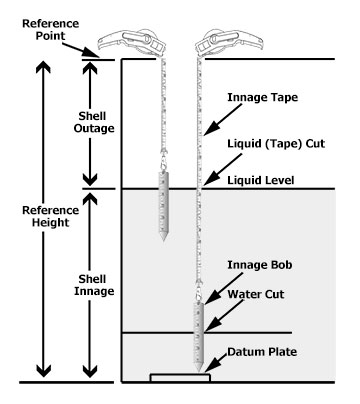

This is a very convenient tool to gauge how much liquid is already in the container. The height of the liquid in the container is directly measured.

The innage oil gauging tape will tell you the actual depth of the liquid from the liquid surface to the bottom of the container. An oil gauging tape measure with a plumb bob is lowered down from the reference point just to the point that the plumb bob touches the bottom of the container or datum plate.

Best Oil Mesuring Gauging Tapes Made in China from Distributor Factory, More Oil Tapes

Care should be taken to lower slowly so the bob does not reach the bottom and then tilt over. This will cause an inaccurate measurement. Also, if the plumb bob hits the bottom of the container with too much force, it can damage or puncture the container. (A new plumb bob that has a rubber end tip help avoid this kind of damage).

When the gauging tape is reeled back up the depth of the liquid in the container, it is read where the oil tape is wet (like a dipstick in a car). Sometimes water-finding paste or oil paste can be used to help show the mark in very thin liquids. Innage oil gauging tapes are used with innage plumb bobs. The zero point of an innage gauging tape is at the bottom of the bob.

Procedure for Innage Gauging Tapes

Place oil indicating paste on the tape where liquid (usually is oil) cut is expected. Place the unmarked side of the tape against the metal rim of the guaging hatch, usually, the reference point.

Lower the tape and bob into the tank until the bob is a short distance from the bottom. To determine this, compare the length of the unwound tape with the reference height of the container.

Unwind the tape slowly until the tip of the bob touches the tank bottom or the tape is not lowered so far into the tank that the bob tilts and causes the tape to go slack To ensure accurate gauging, compare the tape reading at the reference point with the reference height of the container.

Withdraw the tape quickly, and observe the product cut. Record the cut as the innage gage. If the cut is hard to read, put oil-indicating paste on the tape. (Grease or light lubricating oil may be used instead of the paste.) Gage the container again. It is usually easier to see the liquid cut on the back of the tape.

The Outage Oil Gauging Tapes

This is a very convenient tool to gauge how much more liquid can be put in the container. The height of the liquid in the container is indirectly measured.

This is a very convenient tool to gauge how much more liquid can be put in the container. The height of the liquid in the container is indirectly measured.

You can get the distance from the liquid surface to the top of the container (or reference point).

The outage (or top gauging) oil gauging tape will tell you the measurement of the part of the container that is not filled with liquid (the level that has been taken out, or the “ullage”). Because the exact top of the liquid is hard to find, the graduated plumb bob is lowered slowly from the reference point just until it comes into contact with the liquid. Outage oil gauging tapes are used with an outage plumb bob.

The graduations on the outage plumb bob start at the point where the bob is attached to the swivel end clip of the gauging tape, and then get higher. The zero point on an outage gauging tape is where the plumb bob and the end clip of the gauging tape meet. The reading on the bob (marked by the liquid) is added to the reading on the tape at the reference point (at the top of the container. This will give you the total empty portion of the container. Knowing the total depth of the container, you can subtract the space not filled, from the total container depth to determine the depth of the liquid.

The outage gauging is helpful when measuring caustic or thick liquids, as the actual tape measure blade never gets submerged but it is not as accurate as the innage gauging for determining the actual level of liquid in the container.

Procedure for Oil Outage Gauging Tapes

The free space in the container you find by measuring of the free height on the tape minus the length of the plumb bob that dived into the liquid.

To get an outage gage or ullage using the innage tape, and bob.

Lower the tape and bob into the container until the bob touches the surface of the oil.

Wait until the bob stops moving. Lower the tape slowly until the bottom of the bob is 2 to 3 inches below the surface of the oil. Record the reading on the oil gauging tape at the reference point as the tape reading.

Withdraw the tape quickly, and record the oil cut on the bob as the bob reading. It is the cut is hard to read, put oil-indicating paste on the bob and gage the container again.

To get the outage gage, subtract the bob reading from the tape reading. For example, if the tape reading is 7 feet 5 inches and the bob reading is 4 inches, the outage gages is 3 feet 5 inches.

To convert the outage gage to innage gage, subtract the outage gage from the reference height of the container.

Measuring Water Depth Under the Oil

At the bottom we find sediment and water. To measure bottom sediment and water, do the following:

Apply a thin, even coat of water-indicating paste to the portion of the gage stick or plumb bob that will be at the interface of water and oil. Do not apply an excessive amount of paste. This increases the time it takes for the water to react with the paste.

Leave the gage stick in position for 5 to 30 seconds for heavier oils.

Take the gage stick from the container, and look at the water cut on the scale. The water should either remove or discolor the paste on the portion of the scale that was in the water. Record the water cut as either water innage or outage.

|

|

|

|

|

LOMT-OIP Oil Indicating Paste |

LOMT-WIP Water Indicating Paste |

LOMT-Model YX Antistatic Sampling Line |

LOMT-LS-Series Liquid Oil Thief |